Complete Project Services

Complete Project Services

Leveraging our years of experience and industry knowledge we have enjoyed success in delivering major long-term projects, always putting safety first.

As a full service operation, B&R manages all aspects of the project from:

- Conceptualisation

- Design and Engineering

- Manufacturing

- Electrical Integration

- Testing and Validation

- Supply Chain Management

- Project Management

- Warehousing and Distribution

Design, prototyping and engineering

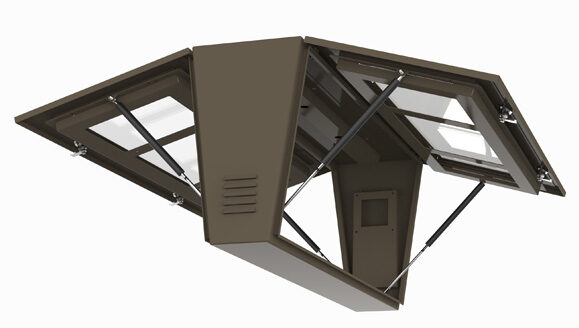

B&R provides specialised solutions through modifications to our existing range of standard products or design and engineering of custom-built enclosures. Our Australian manufacturing sites are capable of producing enclosures to almost any specification, including hazardous environments and sensitive equipment housing.

Manufacturing Capabilities

B&R continuously invests in state-of-the-art machinery, cutting edge technology and rigorous testing processes. These investments allow us to effectively meet and exceed our customer’s evolving needs while maintaining competitiveness and efficiency. Our current capabilities include:

- Purpose-built Australian facilities in Brisbane, Adelaide and Sydney

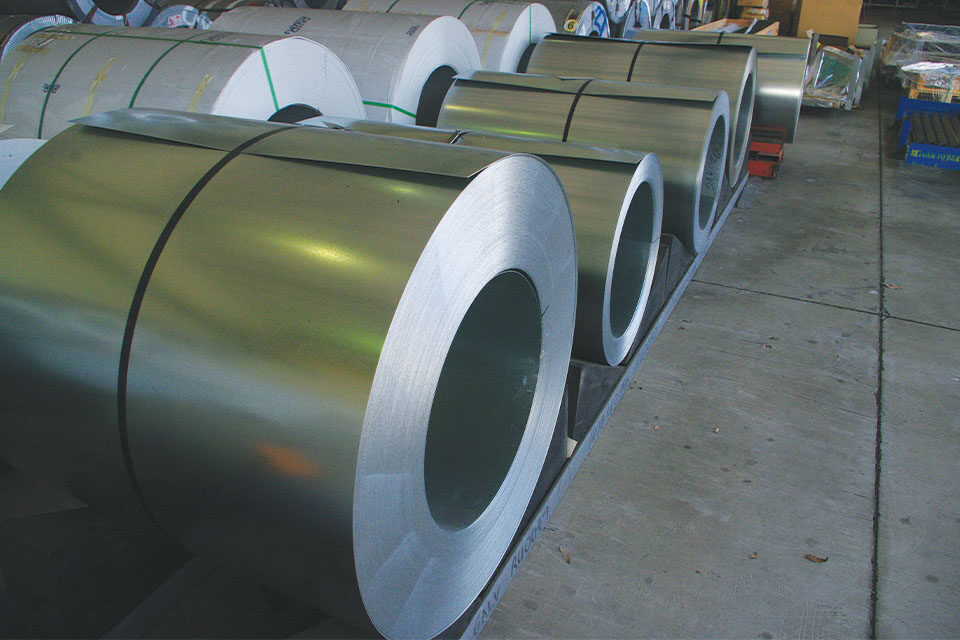

- End-to-end manufacturing, from coiled steel raw material to commissioning the end product.

- Variety of substrates and high-quality finishes including stainless steel, powder coated and zinc.

- Modern machinery including automated sheet metal panel benders, punching and shearing centres, electrical equipment integration lines, press brakes, powder coat lines, fabrication cells and assembly lines.

Electrical Integration

B&R’s Electrical Integration service caters for functional devices to be fully installed and wired into enclosures at the time of manufacture, saving time and money. This enables equipment across the project to be standardised, reducing on-going maintenance and costs.

Our team of electricians and electrical engineers are utilised throughout the design and manufacture of products where electrical integration is to be completed by B&R ensuring quality and safety.

B&R's electrical integration solutions include:

- Full wiring with switchgear and components sourced by B&R.

- Integration of free-issued switchgear and other components.

- Partial integration – wire up ready for final components.

Testing

To ensure all national standards and compliance are met, B&R conducts in-house and third-party testing for:

- Environmental - researching climate control of enclosures including cooling solutions for protection of equipment exposed to high ambient temperatures and solar radiation.

- Temperature rise, impact, IP, type-testing, static load, seismic, wind load, salt spray, line inspection and more.

- NATA Certification of all enclosure products to various protection levels including IP66 and IP67.

- IECEx Certification in-house and external testing for hazardous area electrical equipment.

- Line testing on the enhanced durability of powdercoated enclosures.

Supply Chain Management

B&R prioritises responsible, ethical and sustainable supply chain management. We are experienced in efficiently managing the flow of goods and services, including free issued equipment, from the point of origin to final execution and site delivery. Depending on project requirements, we source and utilise a wide range of raw materials. By employing a Just-in-Time (JIT) methodology we effectively manage costs by keeping raw products in stock.

Project Management

We work closely with our customers to define project scopes and objectives and implement mutual action plans to meet their needs. Project management and execution is made easier at B&R by the co-location of design, supervision, supply coordination and quality control along with manufacturing.

Our incorporation of Industry 4.0 aspects delivers real-time data to our project management teams, who are agile and built around the requirements of individual projects. This means the skill-sets of individual members are compatible to the project and its complexities.

Click here to read more about our full service project management offering.

Delivery

Our proven delivery process ensures we engage in critical communication and status updates at various phases. Utilising lean manufacturing methodology we ensure our processes meet production timeframes.

Our delivery process includes:

- Calculating Delivery In Full and On Time (DIFOT) and Delivery In Full and On Time In Spec (DIFOTIS) and benchmarking quoted lead time against actual dispatch time.

- Tracking our service deliveries against quoted lead times.

- Monthly monitoring and reporting internally.

- Data extracted via our ERP (Enterprise Resource Planning) system and other business tools are available on request.