Order Guide

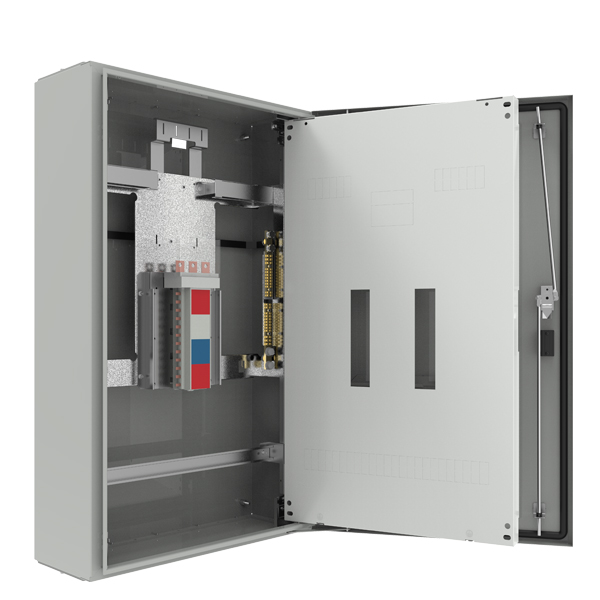

Superior Panelboard – Construction & Features

Superior Panelboard with Switchgear

| Part Number | Height (mm) | Width (mm) | Depth (mm) | Material | CAD Blocks | Enquiry |

|---|---|---|---|---|---|---|

| PBS24P | 1000 | 600 | 250 | Zinc coated steel - RAL7035 | Enquiry | |

| PBS36P | 1100 | 600 | 250 | Zinc coated steel - RAL7035 | Enquiry | |

| PBS48P | 1200 | 600 | 250 | Zinc coated steel - RAL7035 | Enquiry | |

| PBS60P | 1400 | 600 | 250 | Zinc coated steel - RAL7035 | Enquiry | |

| PBS72P | 1400 | 600 | 250 | Zinc coated steel - RAL7035 | Enquiry | |

| PBSEXT | 400 | 600 | 250 | Zinc coated steel - RAL7035 | Enquiry | |

| PBS24P/RO * | 1000 | 600 | 250 | Zinc coated steel - X15 | Enquiry | |

| PBS36P/RO * | 1100 | 600 | 250 | Zinc coated steel - X15 | Enquiry | |

| PBS48P/RO * | 1200 | 600 | 250 | Zinc coated steel - X15 | Enquiry | |

| PBS60P/RO * | 1400 | 600 | 250 | Zinc coated steel - X15 | Enquiry | |

| PBS72P/RO * | 1400 | 600 | 250 | Zinc coated steel - X15 | Enquiry | |

| PBSEXT/RO * | 400 | 600 | 250 | Zinc coated steel - X15 | Enquiry | |

| PBS24P/S * | 1000 | 600 | 250 | 316 Stainless Steel | Enquiry | |

| PBS36P/S * | 1100 | 600 | 250 | 316 Stainless Steel | Enquiry | |

| PBS48P/S * | 1200 | 600 | 250 | 316 Stainless Steel | Enquiry | |

| PBS60P/S * | 1400 | 600 | 250 | 316 Stainless Steel | Enquiry | |

| PBS72P/S * | 1400 | 600 | 250 | 316 Stainless Steel | Enquiry | |

| PBSEXT/S * | 400 | 600 | 250 | 316 Stainless Steel | Enquiry |

*available on request

Accessories

| Part Number | Modules | Accessory |

|---|---|---|

| PF6TR | 6 module width | Pole Fillers |

| PF6TR/PK | 3 x 6 module width |

AS/NZS 61439 Compliance

AS/NZS 61439 is the new series of standards for low-voltage (LV) switchgear and control gear assemblies. For more information on whether you need to comply see our AS/NZS 61439 page.

Click the bar below the requirements and responsibilities for complaince with AS/NZS 61439 for this enclosure.

The following definitions apply to this table: -

- Original Manufacturer* - Switchboard designer and manufacturer of the switchboard enclosure.

- Assembly Manufacturer* - A switchboard builder.

- Original Equipment Manufacturer - The company who manufactured the switchgear used in final assembly.

*The original manufacturer and assembly manufacturer can be the same company or different companies.

If you are a SWITCHBOARD BUILDER this means you are the ASSEMBLY MANUFACTURER and you may be the ORIGINAL MANUFACTURER too. Any switchgear you order will need to be covered by the requirements of the Original Equipment Manufacturer.

B&R has some (but not all) of the responsibilities of the ORIGINAL MANUFACTURER.

If you are an END USER of the equipment you can see who has responsibility from these definitions.

| No | Characteristic to be Checked | Clause | Responsibility | Comments |

|---|